M.S. Candidate: Engin Deniz Erkan

Program: Data Informatics

Date: 06.01.2026 / 13:00

Place: A-212

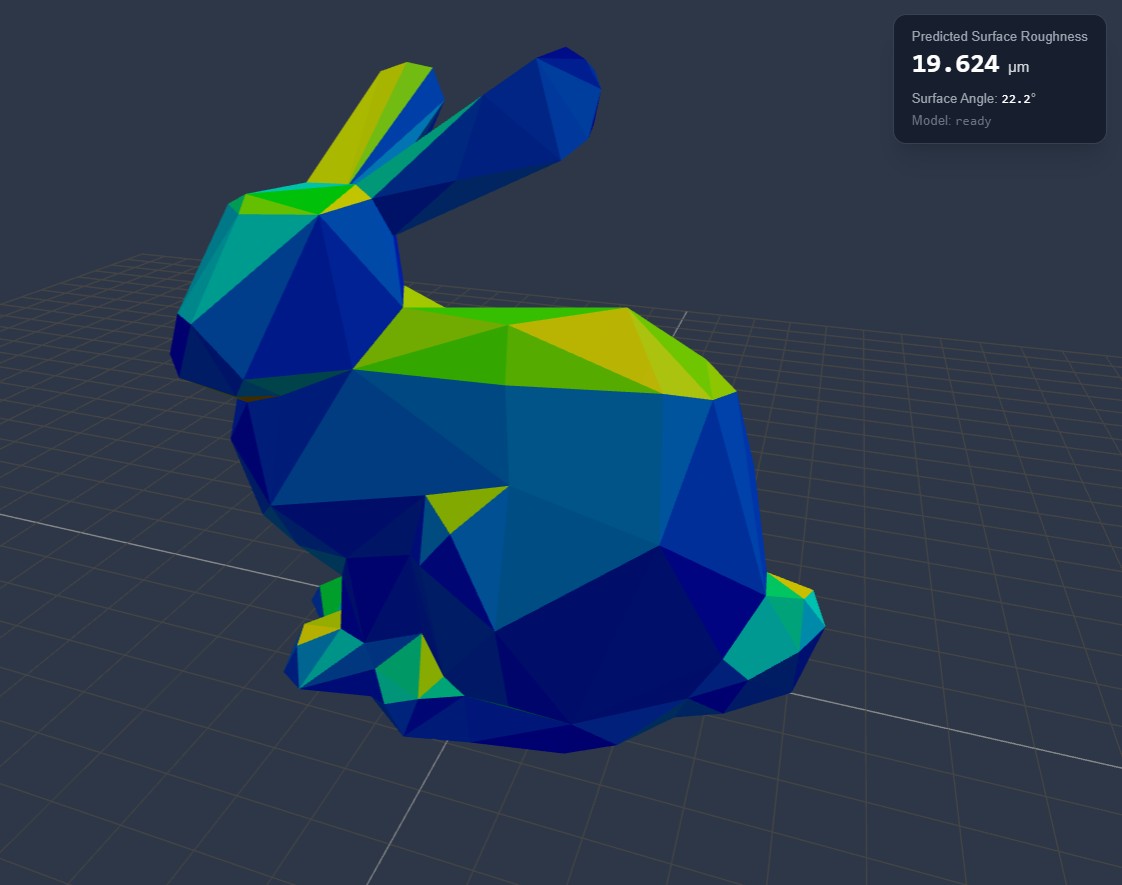

Abstract: Additive manufacturing is a technology that aims to fabricate three-dimensional objects by adding layers of materials on top of each other. However, the surface quality of objects fabricated via additive manufacturing may vary and be difficult to control. This thesis proposes a machine-learning approach to predict the surface roughness of objects which are additively manufactured. The most important characteristics for forecasting surface roughness are investigated in this study using data analysis and machine learning methods. A structured dataset was generated using a three-level Box–Behnken experimental design, comprising profilometer measurements collected from printed parts with multiple surface inclination angles. First, classical machine-learning regressors were trained to establish baseline performance. To better represent the non-linear interactions between printing parameters and surface inclination, a deep learning model based on a multilayer perceptron (MLP) was developed. The MLP was further enhanced using a conditional generative adversarial network (CGAN) to generate realistic, condition-specific synthetic samples, which improved generalization and enabled the MLP to surpass the baseline models. To support practical use, an interactive graphical user interface (GUI) was implemented. The interface allows producers to adjust printing settings and part orientation and to view the predicted surface roughness with real-time updates.