M.S. Candidate: Umut Can Erkan

Program: Multimedia Informatics

Date: 01.09.2025 / 15:00

Place: B-116

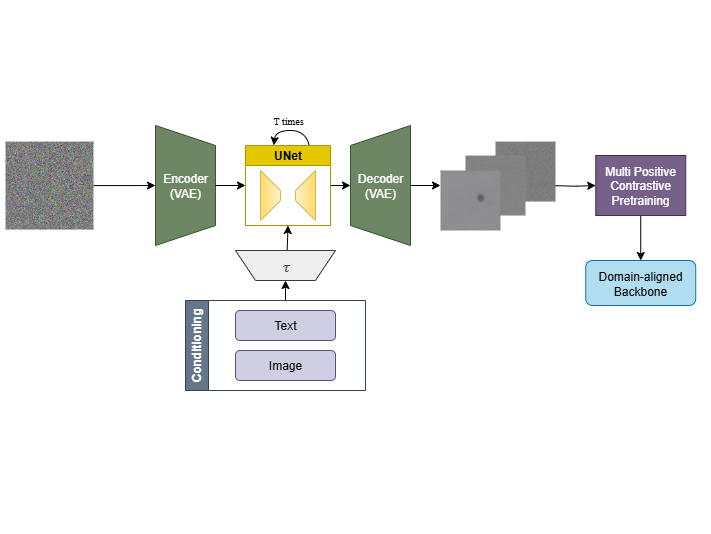

Abstract: Non-destructive testing (NDT) using radiographic imaging plays a vital role in quality assurance for industrial manufacturing, particularly in detecting internal flaws in aluminum castings. However, the application of deep learning to radiographic flaw detection is limited by a lack of publicly available, diverse datasets and domain-specific pretraining strategies. This thesis addresses both challenges by introducing a high-resolution X-ray dataset of aluminum castings annotated according to the American Society for Testing and Materials (ASTM) standards. The dataset covers both coarse and fine-grained flaw categories, such as porosity types, gas holes, inclusions, and shrinkages, and captures variation across materials, perspectives, and flaw severity levels. We benchmark several object detection models on this dataset to establish baseline performance and highlight domain-specific challenges. To overcome data scarcity, we propose a synthetic data generation pipeline using Stable Diffusion with textual inversion. Out-of-distribution synthetic radiographs are generated from only a few publicly available reference images, ensuring reproducibility and eliminating dataset-specific leakage. The resulting synthetic data is used for self-supervised contrastive pretraining, enabling the model to learn defect-aware representations without requiring labeled data. Our pretrained backbone improves the performance of downstream tasks on our dataset, outperforming ImageNet-pretrained baseline. This thesis' main contributions are a challenging new dataset, a dataset-agnostic synthetic data generation pipeline, and empirical evidence that synthetic, out-of-distribution samples can still drive effective self-supervised learning for industrial flaw detection.